Do you want to learn how to safely and effectively get wire out of a mig welder? Looking for a comprehensive guide on this essential task? Then you’ve come to the right place! As a niche expert, I’m here to provide you with the best advice on how to get wire out of a mig welder. I’ll take you through the entire process, from the tools you’ll need to safety precautions and proper wire removal. By the end of this article, you’ll have the knowledge and confidence to tackle any wire removal task with ease. So let’s get started!

What is a Mig Welder?

A MIG welder is an arc welding machine that uses a consumable wire electrode and a shielding gas to weld metals. It is one of the most commonly used welding processes, and it’s used for many different applications in a variety of industries. MIG welding is often used for welding thin materials, but it can also be used for heavier materials with great quality.

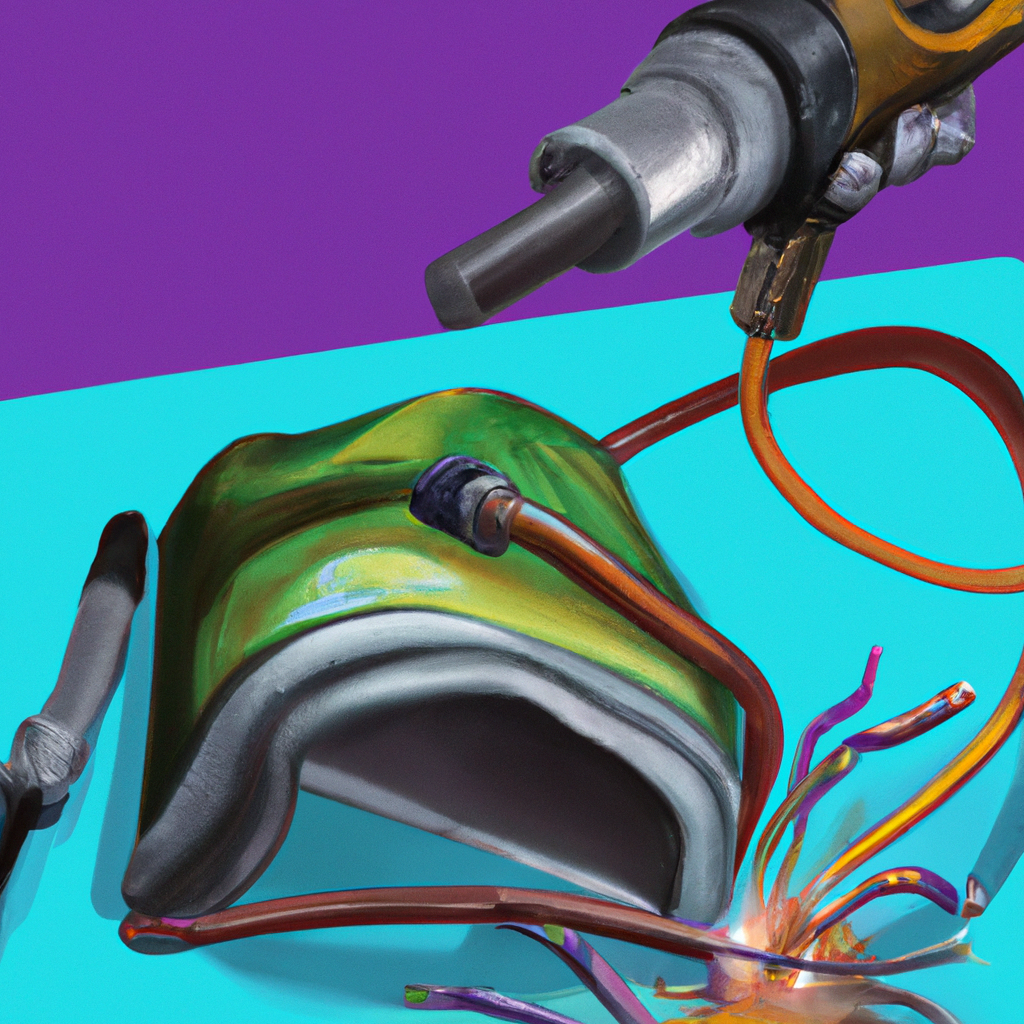

If you’ve ever used a MIG welder, you may have noticed that sometimes there’s wire left inside the gun. This can be frustrating, as it can cause the machine to jam or even damage the internal parts. Fortunately, it is relatively easy to get the wire out of the machine. Here’s how to do it:

- Make sure the welder is unplugged and the gas cylinder is disconnected.

- Remove the nozzle and inspect it. If there is any wire inside, use a pair of needle-nose pliers to carefully pull it out.

- Inspect the liner and make sure there is no wire in it. If there is, use a small screwdriver to carefully remove it.

- Finally, check the power source for loose wire. If there is any, remove it with a pair of pliers.

Once you’ve removed all the wire, reassemble the welder and you’re ready to start welding again. Doing this regularly can help ensure the longevity of your MIG welder and ensure that it works properly when you need it.

What is Wire Used For in a Mig Welder?

Wire is used in a MIG welder to create an electrical arc which melts the wire and fuses it with the metal being welded. It serves as the filler material when welding, and is typically made of mild steel, aluminum, stainless steel, or other alloyed metals. The size of the wire affects the type of weld created, as well as the strength and appearance.

In order to get wire out of a MIG welder, you will need to:

- Open the wire feed compartment

- Remove the wire spool

- Cut off the wire from the spool

- Replace the wire spool with a new one

- Feed the new wire through the feeder

When removing the wire spool, it is important to ensure that the old wire is completely removed from the welder and disposed of properly. It is also essential to ensure that the new wire is fed through the feeder correctly, without any kinks or bends. This will help ensure that the weld is strong and secure.

Once the new wire is in place, the feeder compartment should be closed and the welder should be ready for use. It is important to regularly check the wire feed to make sure it is working properly and that there are no kinks or bends in the wire.

What Tools are Needed to Remove Wire from a Mig Welder?

In order to successfully remove the wire from a Mig welder, you will need the following tools:

- Wire cutters

- Pliers

- Wire strippers

- Safety glasses

- Welding gloves

Begin by putting on the safety glasses and welding gloves to protect your eyes and hands. Then, using the wire cutters, cut through the wire. Carefully remove the wire from the Mig welder and discard it. Next, use the pliers to twist off the contact tip from the Mig welder. Use the wire strippers to strip off the insulation from the new wire. Finally, thread the wire into the contact tip and secure it with the pliers. Your Mig welder is now ready to use.

How to Prepare the Mig Welder for Wire Removal?

Removing the wire from a MIG welder can be a tricky process, but with the right steps, it can be done safely and efficiently.

Here are the steps for how to get wire out of a MIG welder:

- Turn off the power to the welder.

- Unplug the welder from the power source.

- Remove the wire spool from the welder.

- Carefully pull out the wire from the drive rolls.

- Cut the wire if necessary using wire cutters or scissors.

- Remove any remaining wire from the gun.

- Clean any wire residue from the gun.

- Replace the drive rolls if necessary.

Following these steps will help ensure that the wire is safely and efficiently removed from the MIG welder. It is important to remember to use safety gloves and eye protection when removing the wire.

How to Unwind and Remove Wire from the Mig Welder?

Unwinding and removing wire from a Mig welder can be a tricky process. Here are a few steps to help get the wire out of the welder:

- Turn off the power to the welder and disconnect the power cord from the wall.

- Loosen the tension roller and turn the spool pin counter-clockwise until the wire comes out of the gun.

- Unwind the wire so it can be cut off from the spool.

- Make sure the gun and power cord are far away from the spool.

- Cut the wire close to the spool and remove it.

- Once the wire is removed, re-tension the roller and re-spool the wire.

By following these steps, you can easily and safely remove the wire from the mig welder.

How to Dispose of the Used Wire Safely?

Unused wire is a dangerous material to dispose of, as it can be a hazard to people and the environment. Here’s how to safely get rid of used wire:

- Secure the wire and cut it into short pieces, no longer than a foot each.

- Place the pieces in a sealed plastic bag or container.

- Label the bag or container clearly with the material name, date and location.

- Contact your local hazardous waste disposal facility for information on how to dispose of the wire.

You may also consider recycling the wire. Before you do this, check with your local recycling center or scrap yard to see if they will accept wire for recycling. If they do, then it’s a great way to dispose of the wire, while also helping the environment.

How to Clean and Store the Mig Welder After Wire Removal?

After you have finished welding with your mig welder, it is important to properly clean and store the machine. Here is how to get the wire out of your mig welder and store it safely:

- Turn off the power and unplug the machine.

- Take the wire feeder and roll it off the spool.

- Remove any remaining wire from the feeder.

- Remove the liner from the feeder and cut off any remaining wire.

- Replace the liner and re-attach it to the feeder.

- Store the wire feeder in a dry place.

Once you have removed the wire from the machine, it is important to properly clean it. Use a damp cloth to wipe down the mig welder, paying special attention to the gun and the wire feeder. This will help to remove any dirt, dust, and debris that has accumulated during use.

Finally, store the mig welder in a dry, dust-free environment. Cover the machine with a cloth or tarp to protect it from dust and debris. It is also important to make sure the machine is away from any sources of heat or moisture, as this can damage the machine.

By following these steps, you can ensure that your mig welder is properly cleaned and stored for future use.